.jpg)

Figure ##. Victim of USS Aspro (SS-309)

The Torpedoes

Torpedo development

Torpedoes as a weapon began as what we now call mines. Union ADM Farragut went into fame damning them. The modern torpedo was originally known by the name automobile torpedo, indication the charge (the torpedo of the day) was self propelled.[1] This type of torpedo was designed by an Austrian Naval officer in the late 1800s. Since he did not care to work out the details, he sold his idea to an Englishman named Whitehead. This Whitehead became the true father of the modern torpedo. With a virtual monopoly on working torpedo designs, by World War I, all navies were using one version or another of license built Whitehead torpedoes.

“The Gun Club” claimed charge of developing and producing torpedoes. In 1869, BuOrd established NTS Newport, RI, the first facility in any navy dedicated to torpedo development[2]. Quickly the key to Rhode Island economy, NTS Newport started by relying on the Whitehead design and building (although very slowly) exquisitely machined torpedoes. As the major employer in Rhode Island, pork-barrel politics prevented any action that didn’t continue NTS Newport’s existence. This job security soon turned into resistance to change[3]. By 1870, NTS suffered from NIH, refusing to build any foreign designed torpedoes. 1894 found NTS Newport conceding and buying Whitehead torpedo rights[4].

To meet the demands of World War I, the Congressional delegation conceded the need for another NTS facility (subordinate to Newport of course and only for the duration) so NTS Alexandria, VA was opened in 1916 to build Mk X torpedoes. The Mk X carried a 500 lb warhead 3500 yards at 35 knots[5].

Between the German U-boats’ success and the success of small torpedo boats in sinking ships much greater in size than themselves, the torpedo became a feared weapon. In reaction, war ship designs added torpedo bulges (an area below the water line blocking vital innards that was double hulled) or torpedo belts (belts of extra armor below the water line). Since torpedo size could expand only so much, between war years research focused on making the most effective use of the limited explosive carried. The way to beat a torpedo belt or bulge? Let the warhead explode underneath the ship. The physics of water compression only allowed the force to go up and break the keel of the target[6].

In 1923 NTS Newport received Congress’ designation as sole designer/developer/builder/tester of torpedoes in the United States. It was only in 1940, that CAPT Christie broke the monopoly of the pork barrel blocks to reopen NTS Alexandria and build a new NTS at Keyport, WA[7]. The first design to go from idea to produced weapon, the Mk XI was a marvel for its day. Steam driven, with a 21” diameter, the Mk XI had multiple speeds, capable of being selected while inside the closed torpedo tube.[8]

In the 1920s, under the supervision of masters candidate Ralph Christie, NTS Newport began the development of what they termed an influence exploder[9]. While many options received testing, the idea showing the most promise in the labs was a magnetic exploder. The concept was based on the magnetic field of the ship, as delineated in a BuShip (Bureau of Ships) survey of the magnetic field of one captured German battleship on 1920. Between the lack of scientific understanding of the earth’s magnetic field[10] and forced acceptance of the universality of ships magnetic field (as ordered by BuShip), it was inevitable that the magnetic exploder that worked in the stationary lab in Rhode Island might not work reliably.[11]

The resultant exploder, the Mk 6, was an extremely complicated device[12]. It received testing in the ocean once, without a live warhead, at the equator under only one ship[13]. Once those tests worked, the exploder, the instruction and maintenance manual, and all material were classified and securely locked up until war time[14]. The only concession to possible defects was the inclusion of the Mk 4 contact exploder as a back up. The fleet was issued the Mk 5 exploder, a dummy exploder, with the plan being, once war was declared all the Mk 5s would be removed and the Mk 6s would be installed. No training or exposure to the Mk 6 exploder by the enlisted torpedomen who would install and maintain them was allowed.[15]

The Mk 6 exploder was not developed in a complete vacuum. At the same time, torpedoes to utilize the Mk 6 were developed. The series meant to win the next war was the Mk XIII/Mk XIV/ Mk XV series (for aircraft, submarine, and destroyer launching respectively)[16]. The Mk XIII was not capable of using the Mk 6 exploder, but is key in the problems of the Mk XIV as many of the defects of the Mk XIV came from the jointly engineered series. Since these torpedoes would be exploding beneath the target, the size limited 500 lb warhead seemed adequate.[17] The Mk XIII series developed in the 1920s and “perfected” through BuOrd’s “arcane instrument engineering” practices[18] and brought into production in the early 1930s suffered from the Depression like the rest of the nation[19]. Christie’s torpedo/exploder team felt the Mk XIV and associated Mk 6 exploder together were a “mechanical marvel”. Any one who could not sink a ship with this should be replaced.[20]

Live fire testing of a $10,000 torpedo against a real though aged target was deemed prohibitively expensive[21]. NTS Newport and BuOrd shared responsibility for that decision with BuShip and the Navy Department Bureaucracy[22]. Lack of realistic testing outside Newport’s controlled torpedo run would have dire results in the near future[23].

The Mk XIV torpedo, which was the submarine part of the trio, as stated before was developed for the Mk 6 exploder. Steam powered, it had two speed settings. High speed gave 46 knots and a range of 4500 yards. Slow speed gave 31.5 knots for 9000 yards.[24]

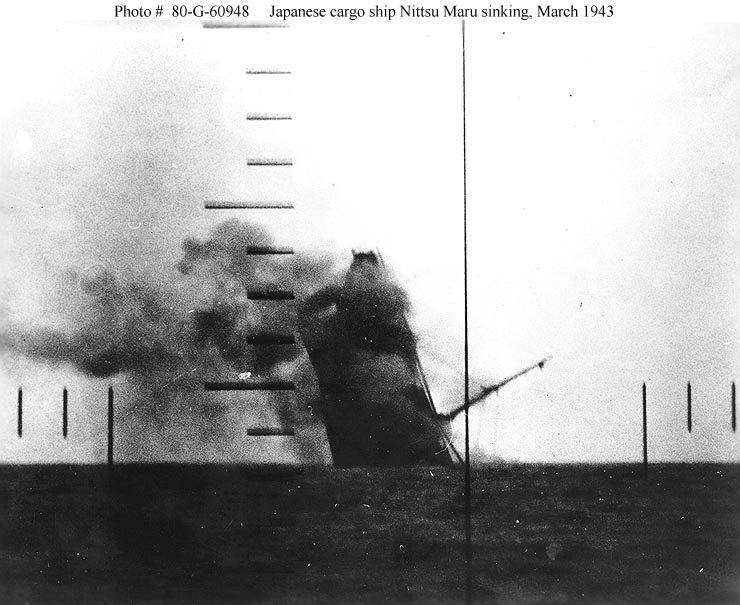

Figure ##. Nittsu Maru. A victim of USS Wahoo.

The Great Torpedo Scandal

December 1941 found the U.S. Navy submarine forces on the front line. The main weapon in their arsenal, the Mk XIV. With more live torpedoes fired in that one month than in all the years between the wars, it should not be a surprise that the Mk XIV was found to be “reliably unreliable.” One commander stated, “ IF it didn’t fail to run, fail to explode, run too deep, explode too soon, or run in a circle, -- the target was doomed.”[25]

RADM English relieved RADM Withers in a normal rotation of duty (as opposed to the many removals for cause occurring around that time) in April 1942. RADM Withers assumed command of NS Portsmouth to be in charge of the submarine construction at Portsmouth and overseen by Portsmouth in other locations. RAMD English became the Pacific apologist for the Mk XIV torpedo and its Mk 6 magnetic exploder. In endorsing submarine commanders’ patrol reports, English and his staff placed the blame for faulty torpedo performance on the crews, maintenance, weather, and any other possible factor they could think of. NTS Newport and BuOrd were never accepted by RADM English as possibly being at fault for failure of the Mk XIV torpedoes to sink ships[26].

April 1942 did bring some hope though. RADM Lockwood assumed duties as COMSUBSOWESPAC. Where English chose to believe the party line, Lockwood from the start backed his skippers[27]. When LCDR Coe (Skipjack) returned from patrol with no torpedoes and no kills, he also brought a meticulous report on the Mk XIV performance. Upon reviewing this report, RADM Lockwood wrote to friend, fellow submariner, and aide to ADM King, RADM Edwards of the woeful performance of the Mk XIVs. Lockwood also drafted a proper and formal report to BuOrd detailing the problems. BuOrd responded with denial. RADM Lockwood commandeered a fishing net from local Australians and using LCDR Coe and Skipjack, conducted live fire tests at Frenchman’s Bay[28]. These were the first controlled tests of live Mk XIV torpedoes and revealed an average depth error of 10 feet too deep. Forwarding these results to BuOrd resulted in an insulting reply from BuOrd stating these were not properly documented results. Lockwood, Skipjack, and the stolen net returned and in the second round of tests, the well and properly documented results gave an average depth error of 11 feet too deep[29]. This time when sending results to RADM Blandy[30] at BuOrd, Lockwood included copies of everything in another letter to RADM Edwards. Edwards shared the letter and documentation with ADM King, himself a qualified submariner, and BuOrd did not get the chance to deny any problems[31]. ADM King gave BuOrd clear and direct orders to test the torpedoes and find the problem[32]. July 1942 belatedly brought BuOrd (not NTS Newport) testing of the Mk XIV. The average error from that round of test was 10 feet[33].

In August 1942, once “official” testing said a problem existed, NTS Newport finally examined the problem. The depth error came from the torpedoes being developed as a series. The depth setting mechanisms were calibrated for the slower and smaller Mk XIII torpedoes. The faster running Mk XIVs actually registered as too shallow.[34] At the same time, the extra weight of a Mk XIV caused it to run nose down. Between the two, an NTS admitted error of 4 feet was possible[35]. BuOrd conducted its own tests and got 10.5 feet. NTS was ordered to design a fix based on the 10.5 foot error[36]. October 1942 found instructions on field modification being transmitted[37]. While this did fix the depth error, torpedoes still were not sinking ships. Now it was realized they were failing to explode[38].

Seawolf[39]’s November 1942 patrol illustrated exploder problems. Carrying a mixed load of Mk X and Mk XIVs, the crew kept carefully documented care of all torpedoes tracking this by serial number. 2 November was a good example of their patrol results. Upon sighting Sagami Maru, Seawolf approached to 1400 yards. Four Mk XIVs were fired. No explosions. Two obsolete Mk Xs were fired. Sagami Maru broke in half and quickly sank[40].

LCDR Jacobs on Sargo tenaciously attacked this problem. Holder of a Masters in ordnance engineering, once Jacobs encountered a premature explosion, he began an engineering analysis that could not be ignored. His first step was to remove all the Mk 6 magnetic exploders and deactivate the magnetic portion[41]. Then the exploders were reinstalled. During that patrol, after each torpedo failure, a systematic troubleshooting procedure was documented to remove any possible errors. The next eleven torpedoes failed to hit or failed to explode. Setting all the remaining depths to zero, Jacobs fired his remaining 12 torpedoes and received no explosions. Breaking radio silence, Jacobs sent a detailed report and returned to port[42].

Likewise, LCDR Benson (Trigger) had been placed in position to sink the carrier Hiyo. Benson fired a full bow load of 6 torpedoes from 1200 yards and dove. The crew noted at least 4 detonations, but the depth

charges of the escorts prevented verification. Trigger received so much damage from this retaliation that eight weeks were needed just to repair the damage. Magic intercepts told the torpedoes had prematurely detonated[43].

RADM English gave one further contribution to the submarine campaign against Japan. He died in a plane crash in January 1943. The importance of this final act was in ADM Nimitz’s selection of a replacement, RADM Lockwood, a commander who already believed his subordinate submarine commanders and tested the Mk XIV and found it faulted.

LCDR Scott (Tunny) did one up on Benson. Maneuvering on the surface at night, Scott succeeded in the submariners dream, he got dead center inside a IJN task force. Firing all ten tubes at three aircraft carriers[44], Scott ordered a crash dive to escape. The crew heard at least seven detonations before the depth charges exploding blocked any other sound. Magic again verified ten fired, ten premature explosions[45]. For VADM Lockwood, this was the last straw[46].

May 1943 brought CINCPACs order to deactivate all Mk 6 exploders[47]. Unfortunately, RADM Christie’s personal involvement in the development of the Mk 6 magnetic influence exploder clouded his judgment. ADM Nimitz restated his order 24 June 1943. Christie refused to order deactivation of the Mk 6 exploders in his AOR until December 1943[48] and then only under direct order from VADM Kinkaid, commander of 7th Fleet[49]. Deactivation of the magnetic portion of the Mk 6 still brought no improved scores[50].

On the night of 11 May 1943, LCDR Laughton (Rasher) fired all 24 torpedoes at one convoy over an 18 hour period. With one ship sunk and others possibly damaged, Laughton’s report noted that at least half failed to explode[51].

On 24 July 1943, Tinosa (LCDR Daspit commanding) intercepted Tonan Maru following Magic intercept orders[52]. Daspit, still cautious about the Mk XIV, carefully fired 15 of his remaining 16 torpedoes. Prior to firing, each torpedo was given complete mechanical checkout by the torpedomen[53]. LCDR Daspit carefully set up each shot and, since there was no escort or fear of aircraft, left the periscope up, watched each torpedo the entire time. Twelve torpedoes were verifiably seen to hit. Only one exploded. Several of the dud hits were seen to deflect up into the air upon hitting. Two were seen to miss. Daspit kept his remaining torpedo to bring back for analysis[54].

August 1943 found LCDR Morton and Wahoo on their second Sea of Japan patrol. In three days, they fired ten torpedoes. Nine missed and the other was seen to break upon impact[55].

Following reading LCDR Daspit’s patrol report, VADM Lockwood order more tests. The first test involved firing torpedoes at the cliffs on Kahoolawe. Orders were to salvage the first dud and bring this live misfired torpedo into Pearl for diagnosis. Only three shots were needed to achieve a dud[56]. When disassembled, the firing pin guides were seen to be so severely warped by impact that the pin had not hit the firing cap hard enough to detonate[57]. So as not to be put off by BuOrd, Lockwood’s next round of tests involved dropping torpedoes[58] from 90 feet up onto steel plates. With the plates steel flat on the dock, all test torpedoes failed to fire the installed smoke charge. When the plates were placed at a 45 degrees, only 50% of the test drops failed[59]. Armed with the data from this, VADM Lockwood set CAPT Momsen to work. Momsen’s diagnosis, the steel firing pin and brass firing pin block guides were bent forward due to the weight of the monel detonator housing and arming gear mounted on the top of the four brass guide posts and self destructed from their own weight[60]; his solution, replace the heavy firing pin block with one machined from aluminum[61] and reposition the four brass guide posts. This was dubbed the PHM (Pearl Harbor Modification). After Momsen was well into a fix, the properly typed detailed reports were forwarded to BuOrd. In October 1943, CDR Galatin took a load of Momsen exploder equipped torpedoes to Kahoolawe.[62] Of the first seven fired perpendicularly to the cliffs, the first six exploded.[63] Momsen had the torpedo shop at Pearl Harbor fabricate firing pin block assemblies from aluminum and reposition the four brass guide posts. BuOrd reluctantly reached the same conclusion as Momsen, but took longer. BuOrd later issued a “brass ball” electrical contact switch modified exploders. Both solutions successfully were fielded the rest of the war.[64]

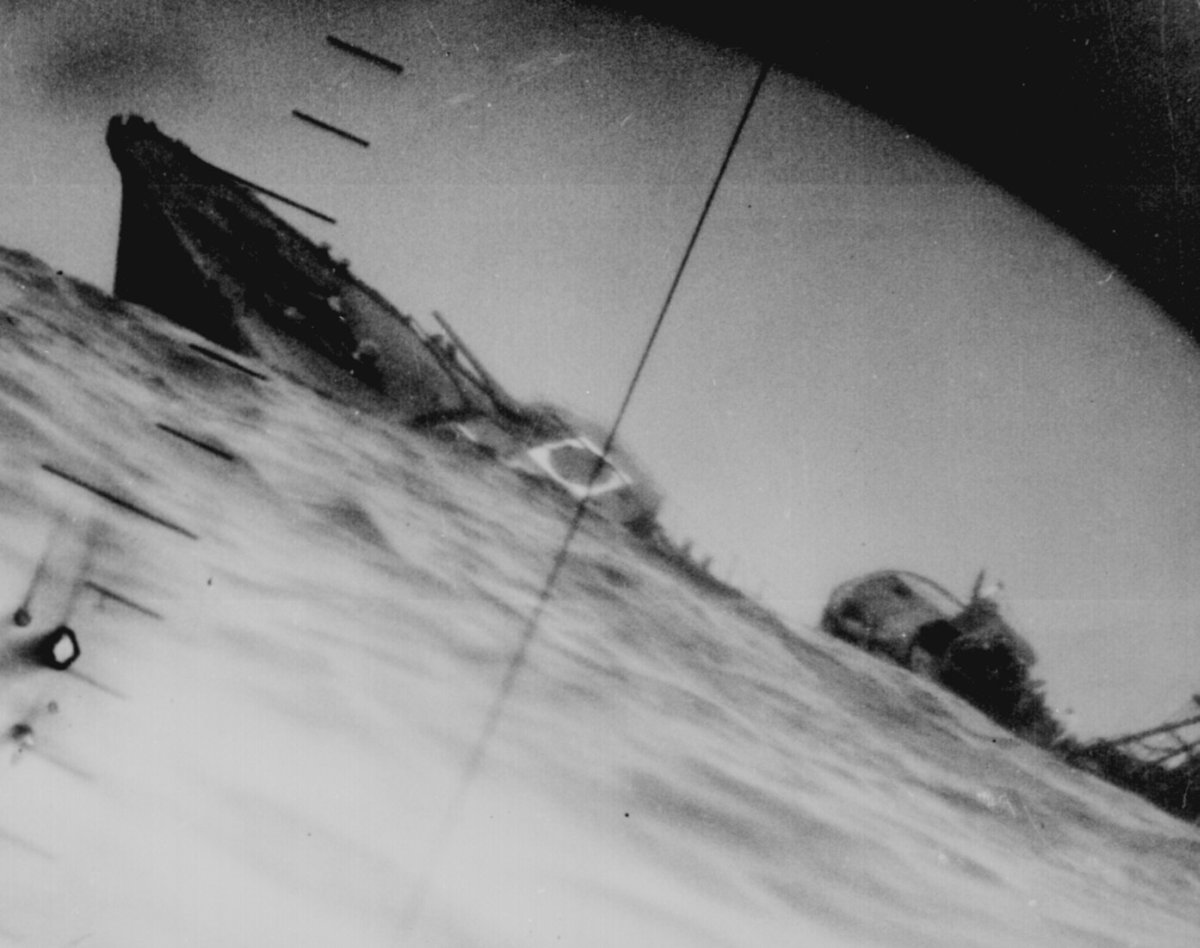

Figure ##. IJN destroyer sinking. Either a victim of USS Wahoo or USS Nautilus.

Light at the End of the Tunnel

By September, 1943, all the Mk XIV defects had been found and fixes were at least designed, if not already installed[65]. A small number of the Pearl Harbor built contact exploders had sailed on patrol. While no immediate jump in the number of sinkings was noted, there was light at the end of the tunnel[66]. A full 21 months into the war, submarines could finally sorties with a reliable weapon. Once these problems were ironed out, the Mk XIII Series proved to be excellent. The Mk XIII continued in service till 1950, the Mk XIV till 1980, while the Mk XV stayed on till destroyers replaced the 21” torpedo[67]. Soon, new torpedoes would join the Mk XIV in breaking Japan[68].

In January 1944, RADM Christie ordered Chester Nimitz, Jr. and James McCallum (who held a masters of ordnance engineering) to study the magnetic exploder and recommend fixes. Christie had the repairs done locally and on 8 March 1944, sent Nimitz, now commanding Haddo, out with a full load of “repaired” Mk 6 exploders. By 12 March, it was clear to Christie that beloved Mk 6 did not work and he admitted defeat[69].

September 1943 had also brought a new torpedo to the war zone. The first trickle of Mk XVIII electric torpedoes were arriving at pearl Harbor.[70]

The U.S. Navy’s electric torpedo program was spurred by 1942 use of electric torpedoes by the German U-boats off American’s east coast. BuOrd began researching An electric torpedo. NTS Newport began to Work on on the MKII. Therefore BuOrd turned to Westinghouse and giving them the salvaged German G7e torpedoes found on American beaches allowed them to run with the program on their own. Westinghouse proposed the fastest solution was to straight up copy the working German torpedo. From this proposition came the Mk XVIII. In June 1942, the first test models were shipped to the only test facility at the time, NTS Newport within 15 weeks of starting the project[71]. They sat there out in the weather with no testing or even care given by NTS. Suffering from severe NIH Syndrome, NTS Newport held up this torpedo from reaching the frontlines by obstrucionism at every turn[72].

Delivered in May 1942 for testing, the Mk XVIII prototypes did not get wet by salt water till June 1943. This required the shanghaiing of Lapon for a test bed since Newport would not cooperate[73].

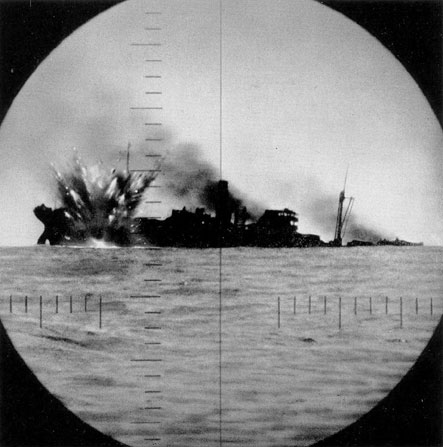

| Figure ##. Hit from Mk XVIII Torpedo. Courtesy of Historic Naval Ship Association. |

September found the first few on war patrols out of Pearl Harbor[74].

The Mk XVIII when first fielded was a direct copy of the German G7e. It ran at 30 knots and left no wake[75]. The original Mk XVIII model had performance problems. Sea water temperature effected the battery’s chemical reaction rate. The time since the last battery charge also showed to be a problem.[76] But since the Mk XVIII was a Westinghouse product, not an NTS Newport heirloom, request for changes went through quickly and easily. Excide began development of a salt water battery in hopes of improving the electric power and reduced weight[77]. By this time, even BuOrd was cooperative[78].

Once in production, the Mk XVIII took the war to Japan. While not initially received with great joy by commanders (it

was slow), by 1945 fully 75% of all torpedoes fired were Mk XVIIIs. LCDR Reich (Sealion II), the XO of Lapon during Mk XVIII testing, sank the only IJN battleship claimed by U.S. Navy submarines (Kongo) with only three Mk XVIIIs[79]. First coming into service in small numbers in September 1943, by August 1945, the Mk XVIII had accounted for 1 million tons of the 4.8 million tons of merchant shipping sunk[80].

One other torpedo came into play for the U.S. Navy in the Pacific[81]. It was the Mk XXVII homing torpedo code named CUTIE. Purpose built to use against escort vessels attacking the submarine, it was small, slow, and short ranged. Derived from an aircraft dropped homing torpedo, CUTIE was 19” in diameter, and had a 10 knot speed. Rather than be pushed out by air like all other torpedoes, CUTIE “swam out” under its own power[82]. With a maximum depth for arming set at 80 feet, submarines fired it underneath attacking escorts (from 100 feet or more down) and it sought out the propeller noise and ran into it. A weak spot on any vessel, it worked well enough to save several submarines. Of the 106 launched, the Mk XXVII achieved a 31% hit rate sinking twenty four ships and damaging an additional nine[83].

In 1944, approximately one half of all Japanese shipping was sunk. Submarine crewmen such as Ned Beach credit this to finally fielding working torpedoes[84]. By war’s end, 14,748 torpedoes had been fired by U.S. Navy submarines in the Pacific. VADM Lockwood maintained the 1944 success rate if used for the entire war would have sunk 4000 ships and the 10 million tons he claimed for “his boys”[85].

The final evaluation of the NTS Newport system should included one post war event. In Fall of 1945, LCDR Freeman at BuOrd authorized the disposal of the remaining World War I stockpile of 43000 Mk IX and Mk X torpedoes valued at $40 million. No sooner had the message been sent to pertinent commands, LCDR Freeman received a phone call from the chief torpedoman in charge of this stock pile. He pleaded to LCDR Freeman, “[But] I have a whole group here. We have a regular maintenance procedure and they’re in perfect shape. We’ve been taking care of them since 1922!”[86]

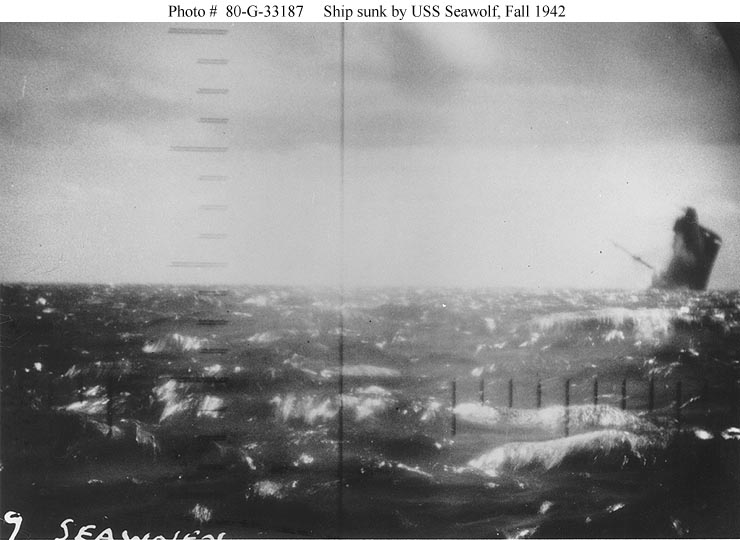

Figure ##. Patrol Boat 39 sinking after hit by USS Seawolf.

Figure ##. Gifu Maru, a victim of USS Seawolf.

[1] Frederick J. Milford. “US Navy Torpedoes.” The Submarine Review April 1996.

[2] Ibid.

[3] Blair. 10.

[4] Milford.

[5] Blair. 20.

[6] Gannon. 76.

[7] Blair. 48.

[8] Milford.

[9] Blair. 34.

[10] Milford.

[11] Ibid.

[12] Ibid.

[13] CAPT Thomas Hart, commander of NTS Newport in 1925, repeatedly requested a real target to sink in a live fire test. BuShip preferred to scrap ships than let them be sunk in testing. Blair. 34.

[14] Specter. 284. Blair. 40-41.

[15] Milford.

[16] The Mk XXIII also could use the Mk 6 exploder.

[17] Blair. 254.

[18] Milford.

[19] Merrigan.

[20] Beach. 21.

[21] A fighter aircraft of the day cost $10,000 without engine. Milford.

[22] Blair. 35.

[23] Merrigan.

[24] Blair. 40.

[25] Merrigan.

[26] NTS Newport, as sole developer of torpedoes denied anything could be wrong as they were the experts and they had developed, designed, and built the torpedoes. Blair. 203.

[27] Padfield. 245.

[28] Milford.

[29] Blair. 250.

[30] Blandy and Lockwood were Naval Academy companions. Their friendship ended with this exchange.

[31] Padfield. 245-246.

[32] Blair. 252.

[33] Ibid. 253.

[34] Milford.

[35] Specter. 284.

[36] Milford.

[37] This change was aimed at correcting two problems, trim change due to warhead weight, and hydrodynamic pressure sensing. The first was caused by the calibration warheads used at NTS Newport were not the same weight as the explosive warshots. This caused the nose of the torpedo to point downward and this caused the torpedo to run about 4 feet deep. More critical was the hydrodynamics of the depth sensor location. The Mk XIII torpedo ran slower than the Mk XIV and XV, but the engineers tested the sensor placement on the Mk XIII and decided it was correct for all three torpedoes. The hydrodynamics of a faster moving torpedo with the sensor placed on the curve of the nose causes the sensor to “feel” a lesser pressure and decide the depth was too shallow. The solution was to place the pressure sensor inside the free-flooding midbody of the torpedo. When calibrated for static pressure, this provided and better depth sensing system. Robert Marble, TMCS(SS), USN (Ret). E-mail dated 10 February 2006.

[38] Specter. 284.

[39] Seawolf began the war in Cavite Philippines on 8 December and by October 1942 had earned two Navy Unit Citations (the 1st submarine to do so)

[40] Beach. 25-28.

[41] This simply involved removing a plug on the forward lower portion of the warhead, withdraw the pick-up rod, and replace the plug. Marble.

[42] Padfield. 186.

[43] Padfield. 347.

[44] Junyo, Hiyo, Taiyo.

[45] Ibid. 346.

[46] Blair. 385.

[47] Milford.

[48] Padfield. 349.

[49] Blair. 475.

[50] Padfield. 350.

[51] Blair. 604.

[52] Padfield. 350.

[53] Ned Beach notes that USN torpedoes required a “ridiculous amount of care”. He noted, British, Dutch and German torpedoes were rugged enough for operational conditions. Labels shipped tied to Mk XIV torpedoes read “Parts not compatible with sea water.” He credits this with the USN torpedomen becoming the best in any navy.

[54] Blair. 409.

[55] Padfield. 352.

[56] Conducted on 31 August 1943. Gannon. 90.

[57] There are four guide posts but the firing pin block assembly rides only on two of them in a vertical direction. Marble.

[58] With practice warheads this time. Enough shorts had been stained in the dismantling of a live warhead last time.

[59] Ibid. 351.

[60] Specter. 285. Marble.

[61] The aluminum used in Momsen’s original firing pin blocks came from aluminum propellers salvaged from Japanese aircraft shot down in the 7 December 1941 attack on Pearl Harbor. Marble 21 July 2006.

[62] Padfield. 354.

[63] With results that good, Lockwood allowed the dud to remain at the bottom this time.

[64] Blair. 410-411. Marble 21 July 2006.

[65] The Mk XIII problems were equally as well documented. One test at Kahoolawe, 100 Mk XIIIs were fired. 31 hit the cliffs and exploded. Most of the failures were multiple failures in on torpedo.

[66] Ibid. 479.

[67] Production totals: 17000 Mk XIII; 22600 Mk XIV and single speed version Mk XX; 9700 Mk XV; 9600 Mk XVIII. Milford.

[68] Specter. 285.

[69] Blair. 583-591.

[70] Blair. 479.

[71] Milford.

[72] ADM King shattered NTS Newport’s power over this final straw. Blair. 256.

[73] Gannon. 139-140.

[74] Ibid. 145.

[75] Padfield. 351.

[76] Blair. 480.

[77] Gannon implies this was fielded during the war, but Senior Chief Torpedoman Marble points out the first torpedo to use a sea water battery was Mk XXIX passive acoustic torpedo, which was just an improved Mk XXVIII. This was not fielded till after World War II.

[78] Gannon. 145.

[79] Ibid. 146.

[80] Milford.

[81] A very small number of Mk XXVIII homing torpedoes made it to the Pacific before the war ended. 14 were fired for 4 hits.

[82] Gannon, p 143.

[83] Ibid. 200-202.

[84] Beach. 261.

[85] Blair. 853.

[86] Gannon, p 201-202.